CASE PACKER

CASE PACKER

▣ Wrap-Around Packer | FW-748

MAX speed : 33case/min

| A | B | C | L | W | |

| MIN. | 150 | 100 | 130 | 500 | 250 |

| MAX. | 400 | 350 | 600 | 1,300 | 900 |

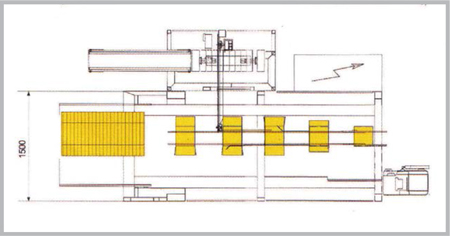

▣ Set-Up Auto Packer | INCASING LINE

Extensive use of limited space, Requires minimum number of workers because forming, incasing and sealing can be done by only one unit.

▶ FEATURE

- Box former, incaser and case sealer in one unit.

- Applicable to various products using different grippers (Applicable to carton box, banknotes, butane gas containers, hot pepper paste container, plastic bottles container, etc.) - Runs stably using the single axis robot.

- Applicable to box former (ABF-TNE, ABF-TEN, ABF-TE and ABF-VT)

- Applicable to case sealer (DH-33ED)

- Incaser : the single axis robot, alignment equipment and box opener unit.

- Box dimensions : Conforms to those of box former and seale

MACHINE SPECIFICATIONS |

(Unit : mm) | ||

| LENGTH | WIDTH | HEGHT | SPEED |

| 4,560 | 1,810 | 2,314 | 8box/min |

▶ UTILTY REQUIREMENTS

- Electrical : 220V/380V/440V, 3-phase, 60Hz

- Pneumatic : 6kg/㎠

▶ OPTIONAL

- Safety cover

- Magazine length : 2,000 / 2,500 / 3,000mm

1. BOX FORMER PART

2. BOX OPENER

3. INSERTING ROBOT

4. CASE SEALER PART

5. CONTROL PART

TURNING SYSTEM

INSERT CON’V

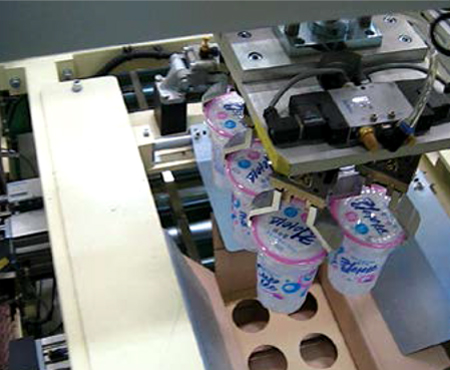

▣ Automatic case packer | INCASING LINE

▶ FEATURE

- Automatically arranges incoming products and puts them in a box.

- In the production line, it works in the order of box former, case packer and case sealer.

- Possible to insert slip sheets between boxes.

- Applicable to various products

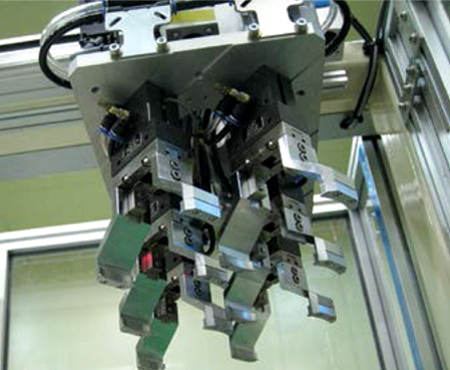

- Different types of gripper (including carton, bag, bottle and can) can be used depending on products. - Servomotor control

- Minimized or no shaking due to the use of servomotor allows performing multiple-point control and applicable to various heights. - Capacity : 8 Box/min

- Product and slip sheet

- It can grip a product while pick up a slip sheet with the suction pad at the same time. - Touch screen

- Selecting auto/manual mode and product type or adjusting work speed, etc on the touch screen. - Product gripper

- Applicable to various types of product

- Possible to perform multiple incasing depending on production amount.

Possible to handle products and insert sleep sheets at the same time

Automatic / manual control on the touch screen.

Arranging products

Opening a box and putting products in

Inserting folded slip sheet in a box

Selecting an suitable gripper

▶ FEATURE

- Automatic arranging products and feeding boxes.

- Multiple point control using servomotors.

- Operation control on the touch screen.

▶ UTILTY REQUIREMENTS

- Electrical : 220V/380V, 3-phase, 60Hz

- Pneumatic : 6kg/㎠

▶ SPEC

- 8cycle/min

▶ APPLICATION CASES

- Hot pepper paste box container and various small carton type

▶ APPLICATION CASES

- Detergent, shampoo, vinegar, PET bottle, etc.

▶ APPLICATION CASES

- Vinegar, cooking oil, PET bottle, soy source container, etc.